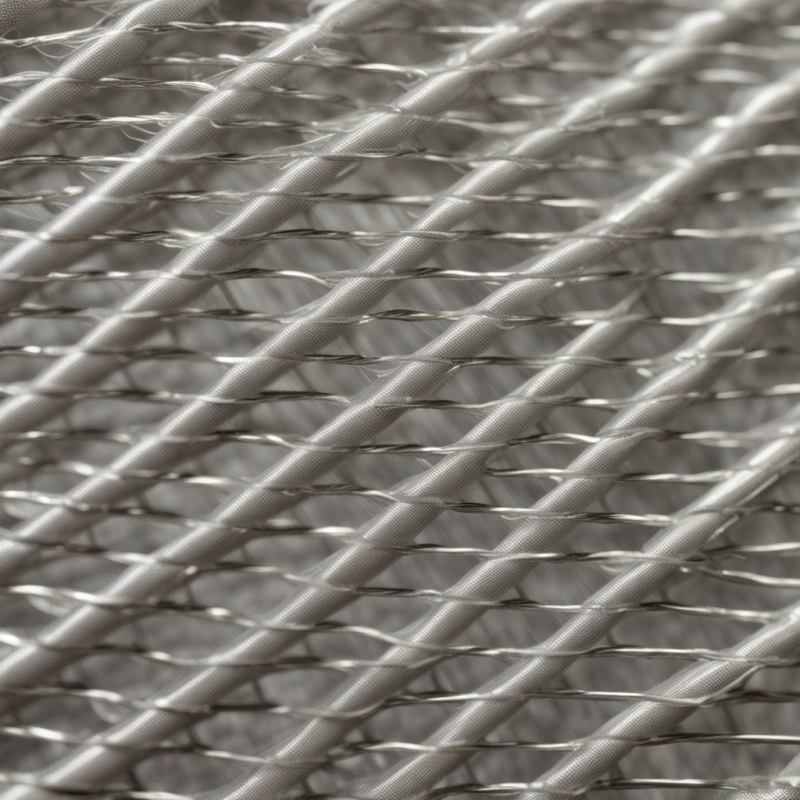

Superior Quality Type A Sintered Wire Mesh: Unparalleled Filtration Applications, Flexible Sizes and Diverse Material Options

ProcurenetShort description

Superior Quality Type A Sintered Wire Mesh is a 5-layer stainless steel fabric ideal for superior filtration needs. Its manufacture involves sintering layers in a vacuum sintered machine, forming a porous material.

- Significant Uses: It’s commonly found in cylindrical filter elements, filter discs, catchers, conical filter elements, and centrifugal clarifiers.

- Dimensions: Standard sizes range from 500x1000mm to 1200x1500mm, and customized sizes can also be made available.

- Material Choices: Predominantly, SS304, SS304L, SS316, and SS316L are used. Nevertheless, special alloy steels like Hastelloy C-276, Monel 400, Inconel 600, SS904, SS904L, and Duplex steel 2205 are also suitable.

-

Procurenet Team Tshim Sha Tsui

Hong Kong 3 years

Description

The Superior Quality Type A Sintered Wire Mesh is a hand-picked product embodying the paragon of cutting-edge technology and reliability for demanding filtration applications. Devised from five layers of high-caliber stainless steel wire mesh, this product is precision-sintered in vacuum sintered equipment. The resultant is an exceptionally porous material offering optimal filtration attributes.

Constructed mainly from SS304, SS304L, SS316, and SS316L, customer-centric customizations are executed using exotic alloys like Hastelloy C-276, Monel 400, Inconel 600, SS904, SS904L, and Duplex steel 2205. The flexibility in material composition augments the endurance and overall efficiency of the mesh.

With standard dimensions spanning from 500x1000mm to 1200x1500mm, the Type A Sintered Wire Mesh fulfills diverse needs by offering the provision of crafting specific sizes within this substantial range according to precise customer specifications.

The mesh’s versatility is aptly showcased by its effortless integration across multiple industry segments. These include:

- Cylindrical Filter Element: Ideal for concerted sectors such as petrochemicals, polyester, pharmacy, food and beverages, water treatment, it delivers superior fluid and gas filtration. Tailoring is available to suit varying requirements of diameters, filter ratings, connection types, and specs.

- Filter Disc: Primarily employed in the pharmaceuticals industry for efficient drying and filtration. It can be morphed into split and integral types.

- Catcher: Designed to capture powder particles in dry gas to curtail powder loss and control air pollution in the pharmaceuticals industry. The dual-tube structure significantly boosts the filter area.

- Conical Filter Element: Widely used in the chemical, pharmaceutical, and beverage sectors, this cone-shaped filter provides excellent diversion, separation, and filtration features.

- Centrifugal Clarifier: Molded into a rotary dynamic filter for efficient filtration and separation in the food, chemical, and pharmaceutical industries.

Specifications:

- Monthly Production Capacity: 12000 square meters

- Packaging: Secure shipment in a wooden case

- Delivery Lead Time: 20 days

- Sample Availability: Option to request a sample

- Payment Terms: T/T