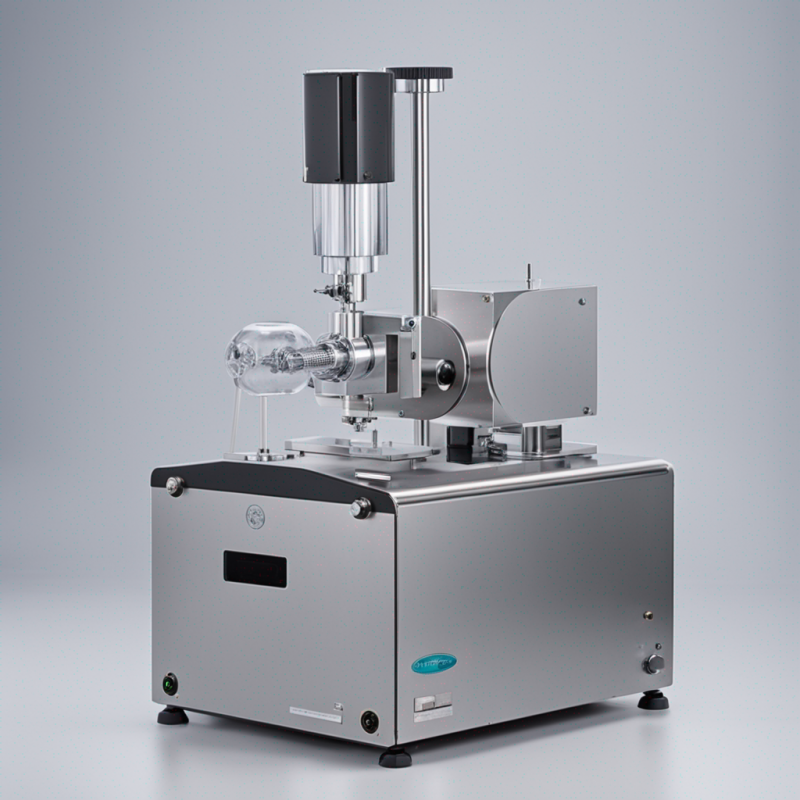

Membrane Extruder/Liposomes Extruder/6 - An Innovative Solution for Pharmaceutical Development

ProcurenetShort description

The Membrane Extruder/Liposomes Extruder/6 is an innovative hot-melt extrusion tool, designed to enhance drug formulation by increasing solubility and enabling sustained release. It is adaptable for various materials with its core design based on a temperature-controlled barrel for sample processing.

- Capacity: Enhances productivity with an efficient 3kg/h workflow.

- Reproducibility: Offers reliable and consistent results.

- Dust-Free Environment: Operates in a closed system for a clean workspace.

- Real-Time Control: Provides maximum performance through online monitoring and adjustments.

-

Procurenet Team Tshim Sha Tsui

Hong Kong 3 years

Description

Membrane Extruder/Liposomes Extruder/6: Revolutionizing Drug Delivery and Material Synthesis

The Membrane Extruder/Liposomes Extruder/6 is a ground-breaking piece of technology that is transforming the fields of pharmaceutical processing and bioengineering. Notably, with its principle of Hot-Melt Extrusion, this technology greatly enhances drug solubility and plays a pivotal role in developing sustainable-release formulations.

Exceptional Technical Attributes

- Efficient processing: With its capacity of 3kg/h, this extruder ensures rapid and efficient processing for high demand settings.

- Precision in manipulation: The 15.6mm screw diameter facilitates highly precise material manipulation, fine-tuning the output to the desired specifications.

- Molding caliber: With a 2mm molding caliber, the output is uniform and streamlined, enhancing product quality.

- Sustainable energy requirements: The tool demands a maximum drive power of 1.5KW, supporting sustainable manufacturing practices.

- High-speed processing: The extruder operates at a maximum speed of 600rpm, allowing for swift preparation and reducing turnaround times.

Unique Advantages of the Hot Melt Extruder

- Consistency: Continuous production couple with superior reproducibility are standout features of this vibrant technology.

- Work environment: The technology is dust-free, hence providing a clean and pollutant-free work setting.

- Control: Real-time monitoring and control features make it an intelligent tool for modern manufacturing setups.

Applications: Proven and Multipurpose

The Membrane Extruder/Liposomes Extruder/6 has dramatically improved the formulation of various products including Adalat SL, Cris-PEG, Kaletra, and Rezulin. Aside from pharmaceutical uses, this extruder is also beneficial in the creation of accessory reinforcing materials such as PEG, Copovidone, and Povidone.

Operating Principle

The Hot-Melt Extrusion process involves the heating of two or more samples in a temperature-controlled chamber until they reach a molten state. The extruder's screw chops and mixes the samples, creating a product with uniform shape and dimensions. By incorporating multiple screw segments with different functions in the axial space, this machine enables ideal size reduction, penetration, and exchange, ensuring flawless mixing and standardized output.